Hyundai’s innovative Vest Exoskeleton wins Red Dot Design Award

The Hyundai

Motor Group’s latest exoskeleton wearable robot, the Vest Exoskeleton (VEX),

has won the Product Design category (Innovative Product field) at the Red Dot

Design Awards.

The VEX was

developed in line with Hyundai Motor Group’s commitment to the health and

safety of its industrial workers. It is designed to prevent injuries while

advancing the field of robotics, earning praise from judges at the 60th

annual international Red Dot Design competition.

“This award is

a testament to the collaboration between the Robotics Lab and the Hyundai

Design Centre,” said Dong Jin Hyun, head of the Robotics Lab at the Hyundai

Motor Group. “Under Hyundai’s brand vision of ‘Progress for Humanity’, our lab

has been trying to pioneer robotics through converging various technologies.

Thanks to the success and recognition of VEX, Hyundai will continue developing

novel products that will provide people with better life quality.”

At 2.5kg, the

VEX weighs 22 to 42% less than competing products and is worn like a backpack.

The user places their arms through the shoulder straps of the vest, then

fastens the chest and waist buckles. The back section can adjust in length by

up to 18 cm to fit a variety of body sizes, while the degree of force

assistance can be adjusted over six levels.

The compact

design is achieved using the latest technology that eliminates the need for a

battery. The VEX uses a polycentric axis – combining multiple pivot points with

multi-link muscular assistance – to provide a maximum force of 5,5 kgf

(kilogram-force), which is an astonishing achievement considering its low mass.

To put it in

perspective, consider that 1 kilogram-force (a non-standard measurement that is

not classified in the International System of Units) is equal to 9,81 Newton.

One Newton is the force needed to accelerate 1 kg of mass at the rate of 1 metre

per second squared in the direction of the applied force.

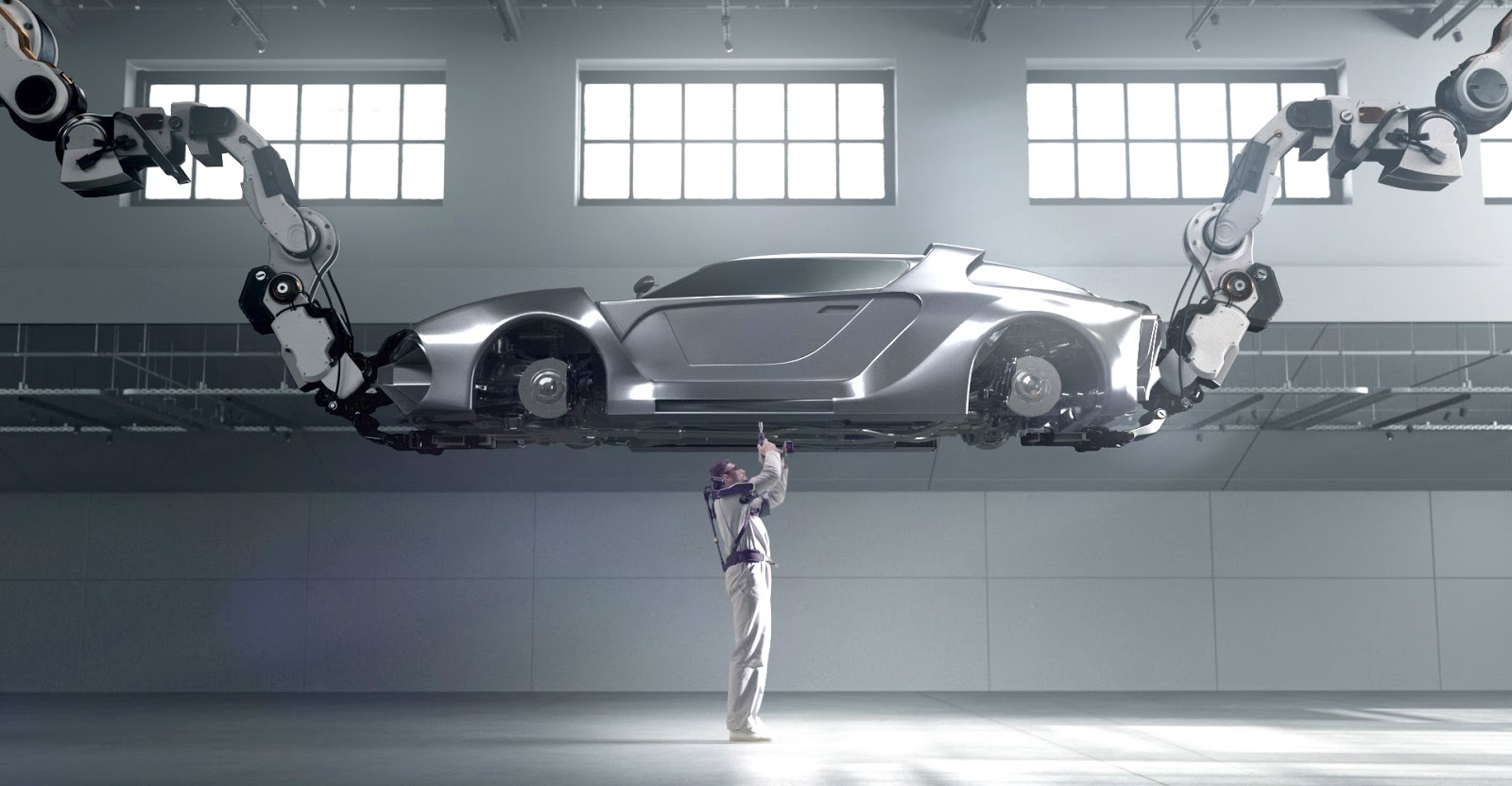

The VEX is

designed primarily for production-line workers who need to work with their

hands above their heads, usually on the underside of vehicles on the assembly

line. The VEX has already won the hearts of workers who have used it. Hyundai

Motor Group ran pilot programs in its US plants, receiving positive feedback

from the workers as it reduces fatigue in their arms and shoulders, while

boosting productivity and safety.

In addition to

the VEX, Hyundai Motor Group is working on another lightweight wearable robot,

the Chairless Exoskeleton (CEX), which will enable workers to easily maintain a

sitting position without a stool or chair.

The Hyundai Motor Group has also unveiled the Medical Exoskeleton,

MEX, and, building on these wearable robots, Hyundai Motor Group plans to

develop more products that will enhance productivity and work safety, and

support rehabilitation of injured patients.

Comments

Post a Comment